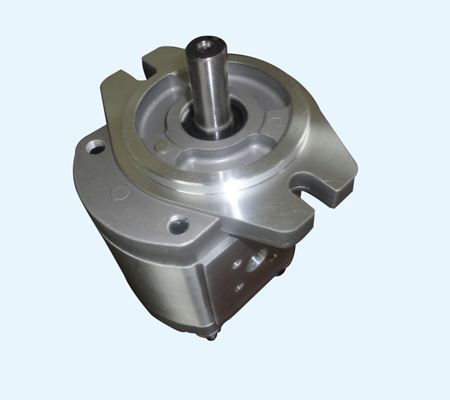

Gear pump maintenance

- As the use time increases, Lubrication gear pumps in the hydraulic system will have insufficient pump oil, or even not pump oil fault, the main reason is that the relevant parts wear too much.

The wear parts of gear pump mainly include active shaft and bushing, center hole of passive gear and shaft pin, inner cavity of pump shell and gear, end face of gear and pump cover, etc.

When the main technical indexes oil transport pumps fail to meet the requirements after wearing, the oil pump should be disassembled and decomposed, the wear parts and degrees should be checked, and the corresponding measures should be taken to repair.

Repair after wear of driving shaft and bushing

After the gear pump driving shaft and bushing wear, its matching clearance increases, will affect the oil pump.

In case of this, it can be used to repair the driving shaft or bushing method to restore its normal matching clearance.

If the active shaft is slightly worn, simply press out the old bushing and replace with a standard size bushing, and the clearance can be restored to the allowable range.

If the active shaft and bushing wear seriously and the fit clearance is seriously out of line, not only should the bushing be replaced, but the active shaft should also increase its diameter by chrome plating or vibration surfacing method, and then grinding to the standard size to restore the matching requirements with bushing.

- Repair of shell crack of lubricating oil gear pump: shell crack can be repaired by casting 508 nickel copper welding electrode.

The weld shall be tight and the air hole, and the flatness error of the joint surface with the pump cover shall not be greater than 0.

5 mm.

Repair of active shaft bushing and driven shaft bushing wear: after the active shaft bushing wear, the wear marks can be eliminated by the method of reamer, and then the bushing with the size increased.

The wear marks of driven shaft holes are eliminated by the method of reamer, and then the driven shaft is prepared according to the actual size of the reeled hole.

Repair of the pump housing cavity: after the pump housing cavity wear, the general adopted the inner cavity insert method repair, after lining the cavity is inserted with cast iron or steel bushing.

After the insert, the inner cavity is lined up to the required size, and the lining sleeve of the outlying end surface is ground to make it level with the joint surface of the pump shell.

Seat repair: pressure limiting valve has ball valve and plunger valve two types.

After the ball seat is worn, place the ball on the seat and gently strike the ball with a metal bar until the ball valve is in close contact with the seat.

If the seat is seriously worn, the grinding marks can be removed by using a numerical control lathe, which can be closed by applying the method.

After plunger seat wear, a small amount of valve sand can be put in to grind until it is firm. - Repair of pump cover

Repair of working plane: if the working plane of the pump cover is less worn, the abrasion marks can be eliminated by manual grinding method, that is, a little valve sand is placed on the platform or thick glass plate, and then the pump cover is ground on it until the abrasion marks are removed and the working surface is smooth.

When the working surface wear depth of the pump cover exceeds 0.1 mm, it should be repaired by turning and grinding first.

Repair of active asphalt pumps shaft bushing: repair of active shaft bushing wear on pump cover is the same as repair of active shaft bushing wear on housing.